Products

Lac is broadly divided into three catagories, i.e, sticklac–the raw material, seedlac–the semi finished material and shellac –the finished product.

Product Profile

Lac is the resinous secretion of the lac insect, parsitic on certain trees like-polas, ber, kusumi principally in bihar, west bengal, madhya pradesh and other indian states. Lac is the only commercial resin of animal origin. It is broadly divided into three catagories, i.e, sticklac–the raw material, seedlac–the semi finished material and shellac –the finished product.

Sticklac

The lac insect, laccifer lacca (kerr), like other scale insects of the super-family coccoidea, is naturally parastic on certain trees and shrubs. In the larval stage it is about 0.5 mm in length, and sufficiently mobile to crawl along the branches of trees to find fress succulent twigs. When it has fixed its position and inserted its proboscis into the trees, it secretes a protective coating consisting of a dark-red chitinous scale similar to cochinea, and a yellow to reddish resin called lac. The life-cycle is about 6 months. Most of the resin is secreted by the female insects.

Seedlac

Removing the sticks, stones etc. As far as possible by crushing, sieving and winnowing, and washing out the dye with water yields the semi-refined product known as seedlac, from its general appearance, in the form of grain of 10 mesh or smaller, and yellow or reddish brown in colour depending on the host tree and the destrict from which the sticklac has been collected. Adhering impurities on these grains of seedlac amount to 3-8 percent, averaging 5%.

The following categories of seedlac is manufactured / commercially used :

Shellac

The shellac is the name of the finished product and is commercially used across the world. It is broadly divided and manufactured in four categories Viz. Handmade shellac, heat process shellac, solvent process shellac, and dewaxed bleached shellac.

Handmade Shellac

Seedlac are filled into long sausage-shaped cloth bags about 2″ diameter and 30′ long. This long bag is passed gradually in front of a charcoal fired hearth hot enough to melt the lac and by twisting the bag the molten lac is squeezed out through the cloth and stretched with the help of a glazed ceramic cylinder.

By handmade process following types of shellac is produced / used / exported :

Heat process Shellac

The shellac is the name of the finished product and is commercially used across the world. It is broadly divided and manufactured in four categories Viz. Handmade shellac, heat process shellac, solvent process shellac, and dewaxed bleached shellac.

Machinemade shellac is also divided into following sub-categories :

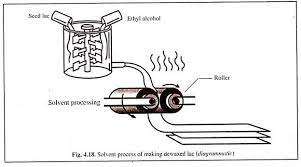

Solvent processes

Seedlac is dissolved in a refrigerated alcohol and filter through filter press to remove wax and impurity. The colour may be removed to any required standard by charging the activated carbon and then alcohol is recovered and molten shellac is stretched on a roller.

The following categories of dewaxed shellac is manufactured with the help of solvent process :

Specification of Dewaxed Platina

| Acid Value | (DAB 9) | 65-80 |

| Ester Value | (DAB 9) | 125-160 |

| Saponification Value | (DAB 9) | 190-230 |

| Melting Range | (DAB 9) | 65ºC-85ºC |

| Wax Content: | (USP XXI) | 0.20% max. |

| Moisture: | 2% max. | |

| Insolubility in Hot Alcohol | 0.10% max. | |

| Rosin Content | Nil | |

| Orpiment | Nil | |

| Arsenic | 1.5 PPM max. | |

| Heavy Metals as Pb | 10 PPM max. | |

| Colour Index | (Gardner in 20% Ethanol Solution) | 6-7 |

| (Lovibond in 20% Ethanol Solution) | 1.75-2.75 |

Specification of Dewaxed Super Blonde

| Acid Value | (DAB 9) | 65-80 |

| Ester Value | (DAB 9) | 125-160 |

| Saponification Value | (DAB 9) | 190-230 |

| Melting Range | (DAB 9) | 65ºC-85ºC |

| Wax Content: | (USP XXI) | 0.20% max. |

| Moisture: | 2% max. | |

| Insolubility in Hot Alcohol | 0.10% max. | |

| Rosin Content | Nil | |

| Orpiment | Nil | |

| Arsenic | 1.5 PPM max. | |

| Heavy Metals as Pb | 10 PPM max. | |

| Colour Index | (Gardner in 20% Ethanol Solution) | 8-9 |

| (Lovibond in 20% Ethanol Solution) | 3.00-3.75 |

Specification of Dewaxed Blonde

| Acid Value | (DAB 9) | 65-80 |

| Ester Value | (DAB 9) | 125-160 |

| Saponification Value | (DAB 9) | 190-230 |

| Melting Range | (DAB 9) | 65ºC-85ºC |

| Wax Content: | (USP XXI) | 0.20% max. |

| Moisture: | 2% max. | |

| Insolubility in Hot Alcohol | 0.10% max. | |

| Rosin Content | Nil | |

| Orpiment | Nil | |

| Arsenic | 1.5 PPM max. | |

| Heavy Metals as Pb | 10 PPM max. | |

| Colour Index | (Gardner in 20% Ethanol Solution) | 11-12 |

| (Lovibond in 20% Ethanol Solution) | 4.00-4.75 |

Specification of Dewaxed Lunar

| Acid Value | (DAB 9) | 65-80 |

| Ester Value | (DAB 9) | 125-160 |

| Saponification Value | (DAB 9) | 190-230 |

| Melting Range | (DAB 9) | 65ºC-85ºC |

| Wax Content: | (USP XXI) | 0.20% max. |

| Moisture: | 2% max. | |

| Insolubility in Hot Alcohol | 0.10% max. | |

| Rosin Content | Nil | |

| Orpiment | Nil | |

| Arsenic | 1.5 PPM max. | |

| Heavy Metals as Pb | 10 PPM max. | |

| Colour Index | (Gardner in 20% Ethanol Solution) | 13 max. |

| (Lovibond in 20% Ethanol Solution) | 5.00-5.50 |

Specification of Dewaxed Lemon

| Acid Value | (DAB 9) | 65-80 |

| Ester Value | (DAB 9) | 125-160 |

| Saponification Value | (DAB 9) | 190-230 |

| Melting Range | (DAB 9) | 65ºC-85ºC |

| Wax Content: | (USP XXI) | 0.20% max. |

| Moisture: | 2% max. | |

| Insolubility in Hot Alcohol | 0.10% max. | |

| Rosin Content | Nil | |

| Orpiment | Nil | |

| Arsenic | 1.5 PPM max. | |

| Heavy Metals as Pb | 10 PPM max. | |

| Colour Index | (Gardner in 20% Ethanol Solution) | 14-15 |

| (Lovibond in 20% Ethanol Solution) | 6.00-6.50 |

Specification of Dewaxed Orange

| Acid Value | (DAB 9) | 65-80 |

| Ester Value | (DAB 9) | 125-160 |

| Saponification Value | (DAB 9) | 190-230 |

| Melting Range | (DAB 9) | 65ºC-85ºC |

| Wax Content: | (USP XXI) | 0.20% max. |

| Moisture: | 2% max. | |

| Insolubility in Hot Alcohol | 0.10% max. | |

| Rosin Content | Nil | |

| Orpiment | Nil | |

| Arsenic | 1.5 PPM max. | |

| Heavy Metals as Pb | 10 PPM max. | |

| Colour Index | (Gardner in 20% Ethanol Solution) | 15.5-17 |

| (Lovibond in 20% Ethanol Solution) | 6.50-7.50 |

Specification of Dewaxed Garnet

| Acid Value | (DAB 9) | 65-80 |

| Ester Value | (DAB 9) | 125-160 |

| Saponification Value | (DAB 9) | 190-230 |

| Melting Range | (DAB 9) | 65ºC-85ºC |

| Wax Content: | (USP XXI) | 0.20% max. |

| Moisture: | 2% max. | |

| Insolubility in Hot Alcohol | 0.10% max. | |

| Rosin Content | Nil | |

| Orpiment | Nil | |

| Arsenic | 1.5 PPM max. | |

| Heavy Metals as Pb | 10 PPM max. | |

| Colour Index | (Gardner in 20% Ethanol Solution) | >18 |

| (Lovibond in 20% Ethanol Solution) | >9 |

Bleached Shellac

The basic procedure in the bleached process consists in dissolving in aqueous sodium carbonate solution at 90-100 degree celcius, stirring off the solution with sodium hydrochloride and the start filtering after cooling down the temperature of solution. The bleached shellac is reclaimed from the filtered solution with sulphuric acid. The precipitated bleached shellac is ten filtered and washed from water for removal of acid and dried.

Bleached shellac is manufactured / exported in following two grades :

Specification of Dewaxed Bleached Shellac

| Acid Value | 65-90 |

| Ester Value | 135-195 |

| Saponification Value | 200-260 |

| Melting Point (Capillary Method) | 75ºC-91ºC |

| Wax Content: | 0.20% max. |

| Moisture: | 6% max. |

| Insolubility in Hot Alcohol | 0.10% max. |

| Rosin Content | Nil |

| Ash Content | 0.50% max. |

| Heavy Metals | 10 PPM |

| Colour | Pale Yellow |

| Arsenic | Nil |

| Iron | Nil |

Specification of Waxy Bleached Shellac

| Acid Value | 65-90 |

| Ester Value | 135-195 |

| Saponification Value | 200-260 |

| Melting Point (Capillary Method) | 75ºC-91ºC |

| Wax Content: | 5.50% max. |

| Moisture: | 6% max. |

| Insolubility in Hot alcohol | 1% max. |

| Rosin Content | Nil |

| Ash Content | 0.50% max. |

| Heavy Metals | 10 PPM |

| Colour | Pale Yellow |

| Arsenic | Nil |

| Iron | Nil |

Aleuritic Acid (Shellac Aleuritic Powder)

Aleuritic Acid (9, 10, 16-trihydroxypalmitic acid), obtained from shellac by saponification, is a unique acid containing three hydroxyl groups of which two are of adjacent carbon atoms.

Shellac Aqueous Solution

Shellac Aqueous Solution is formulated using natural ingredients and is suitable for a wide range of coating applications. It is based on Shellac, a unique and versatile natural resin, combined with a volatile alkali to make it soluble in water, thus forming a clear, slightly amber and very stable solution with a solid content of 25%. It is a true solution with a low viscosity and can be used as supplied or diluted with demineralised water.